NADCAP & A2LA ACCREDITED CHEMICAL ANALYSIS with a rapid turnaround

chemical analysis LAB

Performing chemical analysis at MES offers critical benefits, including ensuring material quality and compliance with industry standards. By verifying material composition and detecting impurities, chemical analysis enhances product reliability and safety, preventing potential failures. Chemical analysis aids in material identification, grade verification, and process optimization, ultimately improving manufacturing efficiency. Additional services include contaminant identification, particle analysis and residue testing. Laboratory services are performed to ASTM, ISO, MIL, AWS, API or other specifications.

THE MES CHEMICAL ANALYSIS PROCESS

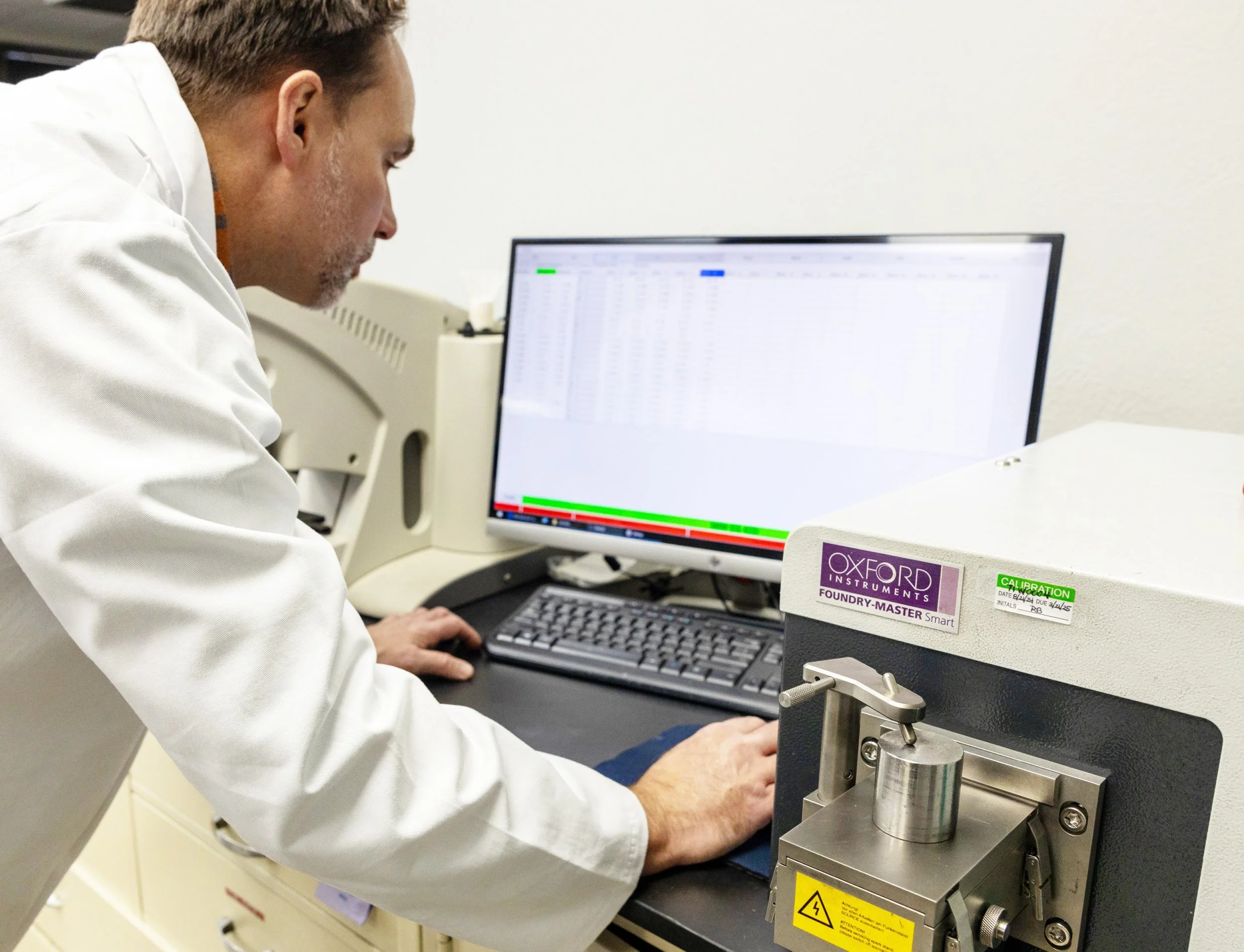

At MES, performing chemical analysis involves a systematic process to ensure accurate and reliable results. The process begins with sample preparation, where the material is carefully collected, cleaned, and prepared to avoid contamination. Advanced analytical techniques such as X-ray fluorescence (XRF), energy dispersive x-ray (EDS) spectroscopy, and optical emission spectroscopy (OES) are then employed to precisely determine the elemental composition of the sample. These methods allow for the detection and quantification of various elements, including trace impurities. The data obtained is rigorously analyzed and compared against industry standards and specifications to verify compliance. Throughout the process, quality control measures are implemented to maintain the integrity and accuracy of the results, providing valuable insights for material selection, quality assurance, and failure analysis.

CHEMICAL ANALYSIS REPORTS

Upon completion of your chemical analysis, a comprehensive report will be provided with data collected and material identification or alloy grade. The core of the report may feature a detailed table of the elemental composition, listing the detected elements and their respective concentrations. Additionally, the report may include a comparison of the results with relevant industry standards and specifications to assess compliance. If needed, any deviations or impurities are highlighted, along with their potential impact on material performance. The report may conclude with an expert interpretation of the findings, offering recommendations for material selection, process adjustments, or further investigation if necessary. Overall, the report provides a clear and thorough understanding of the material's chemical properties, supporting informed decision-making for your material application.

THE MES CHEMICAL ANALYSIS DIFFEReNCE

Our chemists have performed thousands of tests over our 40 years in service and have experience with a wide range of materials and industries. We are focused on providing engineering opinion that allows you to make decisions. Call to talk to our experts and let MES put our experience to work for you.