OVER 35 YEARS OF FAILURE ANALYSIS EXPERIENCE

failure analysis LAB

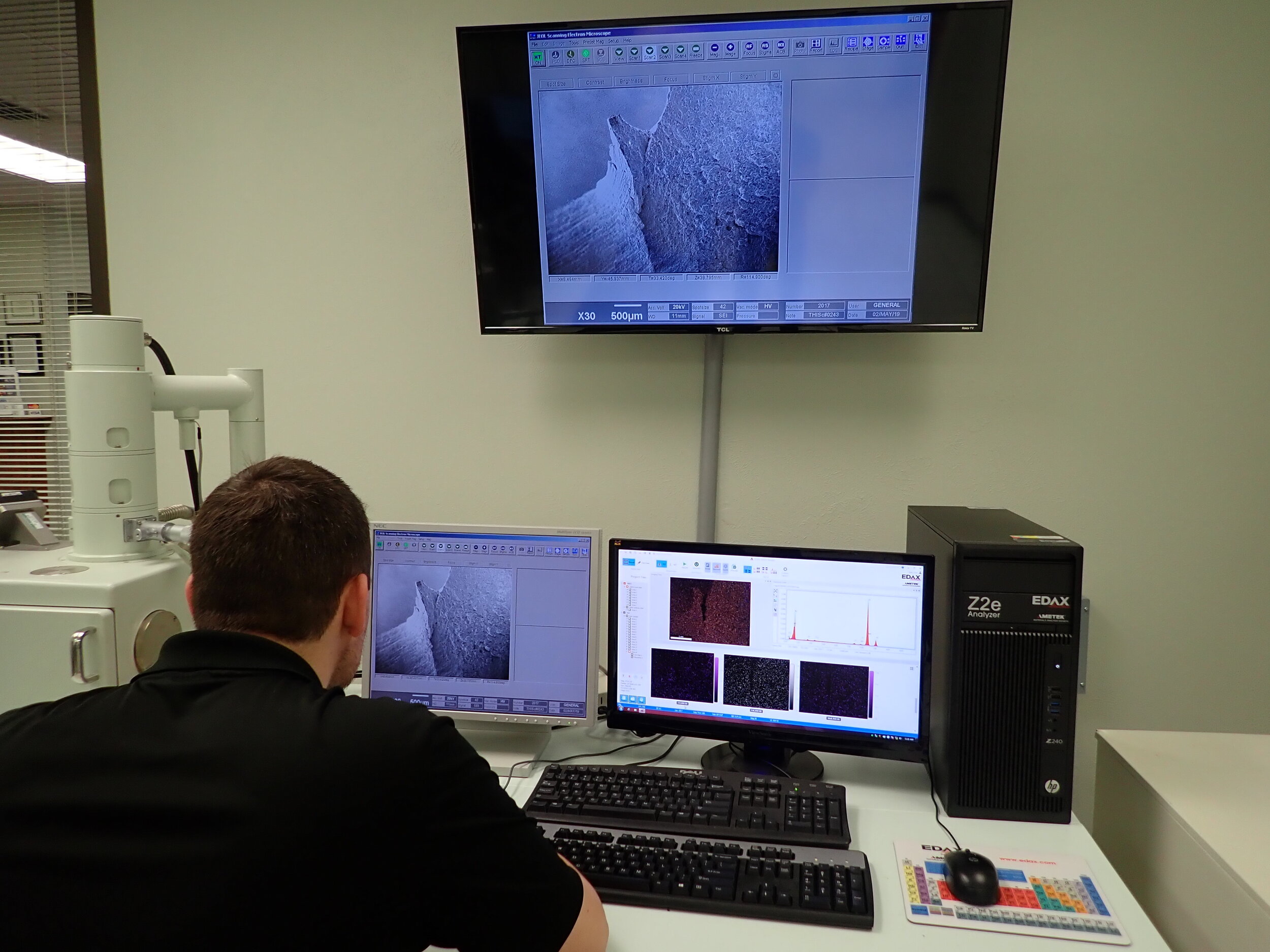

Based in Dallas Texas, MES has the experience and equipment to perform a comprehensive failure analysis for metals, polymers, and composites. Our experts will determine the root cause and provide corrective actions to prevent future failures. When a product fails, it is imperative to perform a thorough investigation. Our team of engineers and materials experts are leaders in determining root cause analysis for material failures. Our depth of materials experience and failure analysis lab allows us to evaluate failures from many different industries, determine manufacturing process problems, detect defects, provide contamination analysis, and evaluate environmental corrosion effects on products.

THE MES FAILURE ANALYSIS PROCESS

Failure analysis is the process of collecting and analyzing data to determine the cause of the failure. Root cause analysis often involves an organized series of tests across multidisciplinary areas. By offering complete materials testing and forensics labs, MES can quickly solve even the most complex failures within one facility. Our laboratories include light and electron microscopy, mechanical and electrochemical testing, chemical characterization, NDT (nondestructive testing) and environmental testing. By determining the source of the failure, we can help to prevent future failures.

FAILURE ANALYSIS REPORTS

Upon completion of your failure analysis, a comprehensive Failure Analysis Report will be provided with conclusions on the root cause of failure conclusions and data supporting those conclusions. The failure analysis report may include remediation actions or recommendations to prevent future failures. Failure analysis reports typically include the following:

Description of the failed component

Background and service history

Visual inspection and fractography of failure

Mechanical, chemical and metallurgical properties data

Comparison to material specifications and control

Discussion of mechanisms that explain the root cause of the failure

Hard conclusions on root cause of failure and recommendations for improvement

THE MES FAILURE ANALYSIS DIFFEReNCE

Our failure analysis experts have performed thousands of root cause investigations over 35 years and have experience with a wide range of failure modes, materials and industries. We are focused on providing engineering opinion that allows you to make decisions and prevent future failures. Call to talk to our experts and let MES put our experience to work for you.

LAB CAPABILItieS

Specifications

ASM Handbook Volume 11

Sample Requirements

Accessibility to test area if field visit required

History of sample, if known

Capabilities

Root Cause Analysis

Contaminant Analysis

Onsite Investigation

Material Selection

Welding Analysis

Forensic Investigation

Corrosion Testing

Pipe Failure Analysis

Metallographic Analysis

Fracture Mode & Mechanism

Particle Analysis

Overheating Investigation