Mes has provided independent materials testing, failure analysis, INSPECTION, and engineering consulting services for over 40 years.

ABOUT MES

Welcome to Metallurgical Engineering Services (MES), your trusted partner in advanced materials testing, inspection, and failure analysis. Started in 1985 as a family company with humble beginnings, we now have over 40 years of experience in the materials testing industry. MES has established itself as a global leader in the laboratory testing field, delivering unparalleled expertise and precision to clients across a wide range of industries.

OUR MISSION

Our mission at MES is to provide top-tier materials testing and engineering solutions that empower our clients to achieve excellence in their projects. We are committed to delivering accurate, reliable, and timely results that meet the highest industry standards.

OUR EXPERTISE

At Metallurgical Engineering Services, we pride ourselves on delivering top-quality testing, utilizing modern equipment, and providing rapid turnaround times. Our professional staff includes doctorate-level and highly experienced professionals specializing in materials science, electron beam surface characterization, weld inspection, mechanical engineering, and metallurgical engineering. Here’s a closer look at what we focus on:

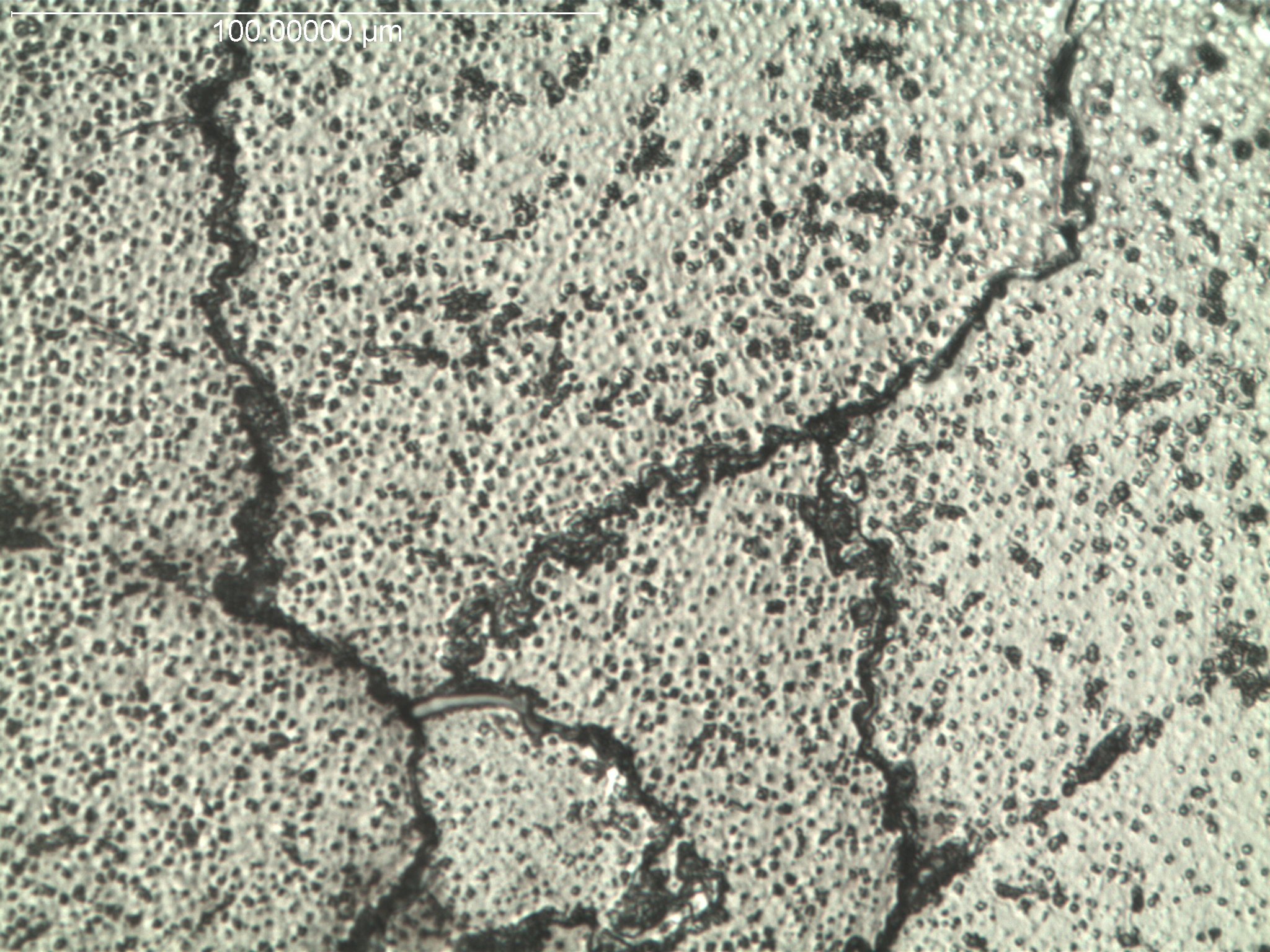

Failure Analysis of Components and Systems: Identify the root cause of failures to enhance the reliability and performance of your materials and systems.

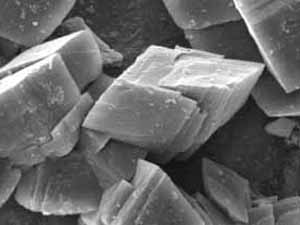

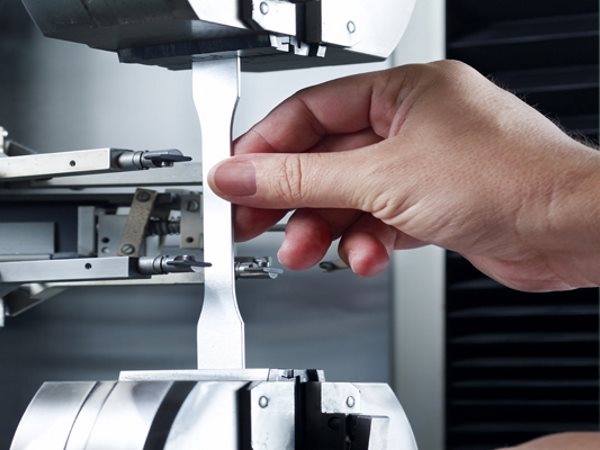

Materials Testing: Our state-of-the-art laboratory offers both destructive and non-destructive testing capabilities for metals, polymers, and composites. We conduct tests to determine mechanical properties, chemical composition, and materials characterization.

Field Inspection of Large Metal Systems: Perform thorough inspections of large-scale metal systems to ensure structural integrity and compliance with industry standards.

Paint and Coating Testing: Evaluate the durability and effectiveness of paints and coatings to protect your materials from environmental damage.

Welder and Weld Procedure Certification: Certify welders and welding procedures to ensure they meet industry standards and safety regulations.

THE MES TEAM

Our professional staff consists of doctorate-level experts and seasoned professionals in materials science, electron beam surface characterization, weld inspection, mechanical engineering, and metallurgical engineering. Their extensive knowledge and experience enable us to tackle even the most complex materials challenges with confidence.

QUALITY AND ACCREDITATION

MES operates under a stringent quality management system accredited by A2LA to ISO/IEC 17025 and NADCAP standards. These accreditations demonstrate our commitment to maintaining the highest levels of technical competence and quality assurance in all our testing and inspection services.

GLOBAL REACH AND RAPID TURNAROUND

With our primary laboratory located in the Dallas metroplex, MES serves clients from all over the world. We understand the importance of timely results, which is why we offer flexible services with rapid, 24-hour turnaround times. Our facilities are equipped to handle test materials of all shapes, sizes, and quantities, ensuring we can meet the diverse needs of our clients.

Why Choose MES?

Unmatched Expertise: Over 40 years of industry-leading experience and a team of highly skilled professionals.

Advanced Technology: Cutting-edge equipment and methodologies for precise and reliable results.

Quality Assurance: Accredited to the highest industry standards, ensuring accuracy and reliability.

Comprehensive Services: A one-stop-shop for all your materials testing and inspection needs.

Global Service: Serving clients worldwide with exceptional customer support.

Contact Us

Ready to learn more about how MES can support your next materials project? Contact us today to discuss your specific needs and discover the benefits of partnering with a best-in-class materials testing and engineering service provider.