WAVELENGTH DISPERSIVE X-RAY

For rapid, quantitative chemical analysis of small particles, MES offers WDS analysis. Wavelength Dispersive X-Ray Analysis (WDS) is a quantitative x-ray technique used to quickly and simply identify the elemental composition of materials. Applications include particle alloy identification, food product contaminant identification, and metal inclusion analysis. WDS can also be used to determine homogeneity and elemental gradients at boundaries. MES provides rapid alloy identification to airlines and other industries for urgent results.

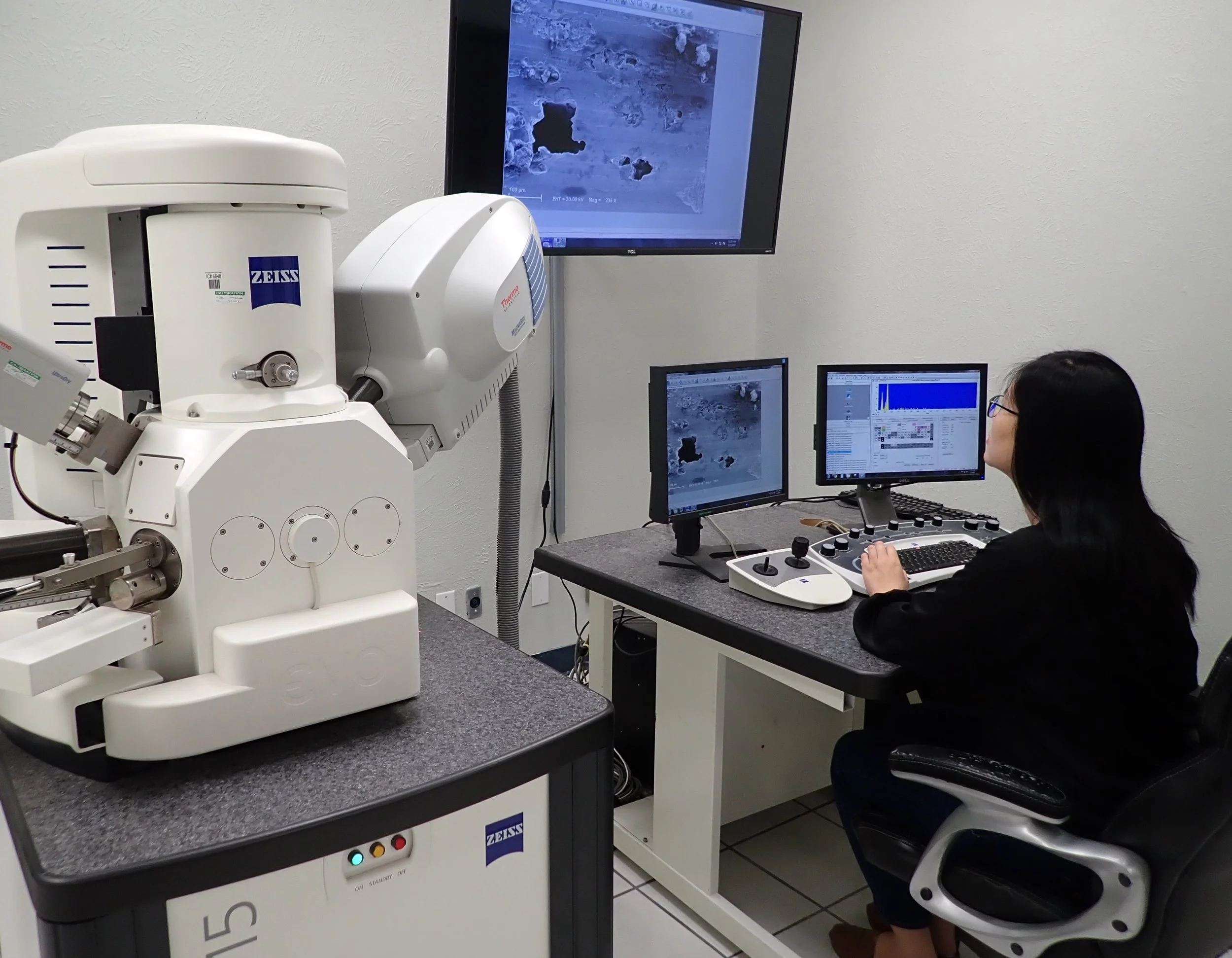

WDS is a surface analysis technique that uses an x-ray beam to produce photoelectrons on the surface of a prepared sample. WDS systems are attachments to the Scanning Electron Microscope (SEM) where the imaging capability of the microscope identifies the specimen of interest. The beam generally penetrates the outer 50 Angstroms of the sample. The photoelectrons are separated and interpreted using diffracting crystals. Quantitative chemical analysis using WDS is achieved by collecting on NIST traceable standards prior to analyzing an unknown composition.

CAPABILITIES

Rapid identification of metal alloys with small sample size

Quantitative elemental composition

Identification of alloy inclusions and phases

Low voltage microanalysis below 5 keV

Magnification – from 5x to 300,000x

Solid inorganic materials

Sensitive for trace elements

SPECIFICATIONS

ASTM E1621 - Elemental analysis by WDS

SAMPLE REQUIREMENTS

Pinhead of material or particle