Micro Hardness

MES offers micro hardness testing of metals and minerals using Knoop and Vickers scales. Located in Dallas, MES has a complete metallurgical laboratory staffed with graduate level materials engineers to supervise all hardness testing projects. Our full-service mechanical lab offers rapid test results at an affordable price. As an A2LA ISO 17025 accredited lab, quality is our focus.

Micro hardness testing of metals, composites and minerals is employed where a superficial hardness test is not possible due to a small sample geometry or area of interest. Micro hardness tests can be used to provide necessary data when measuring individual microstructures within a larger matrix, thin materials, coatings, or when determining the hardness gradient of a specimen along a cross section, such as a weld heat affected zone.

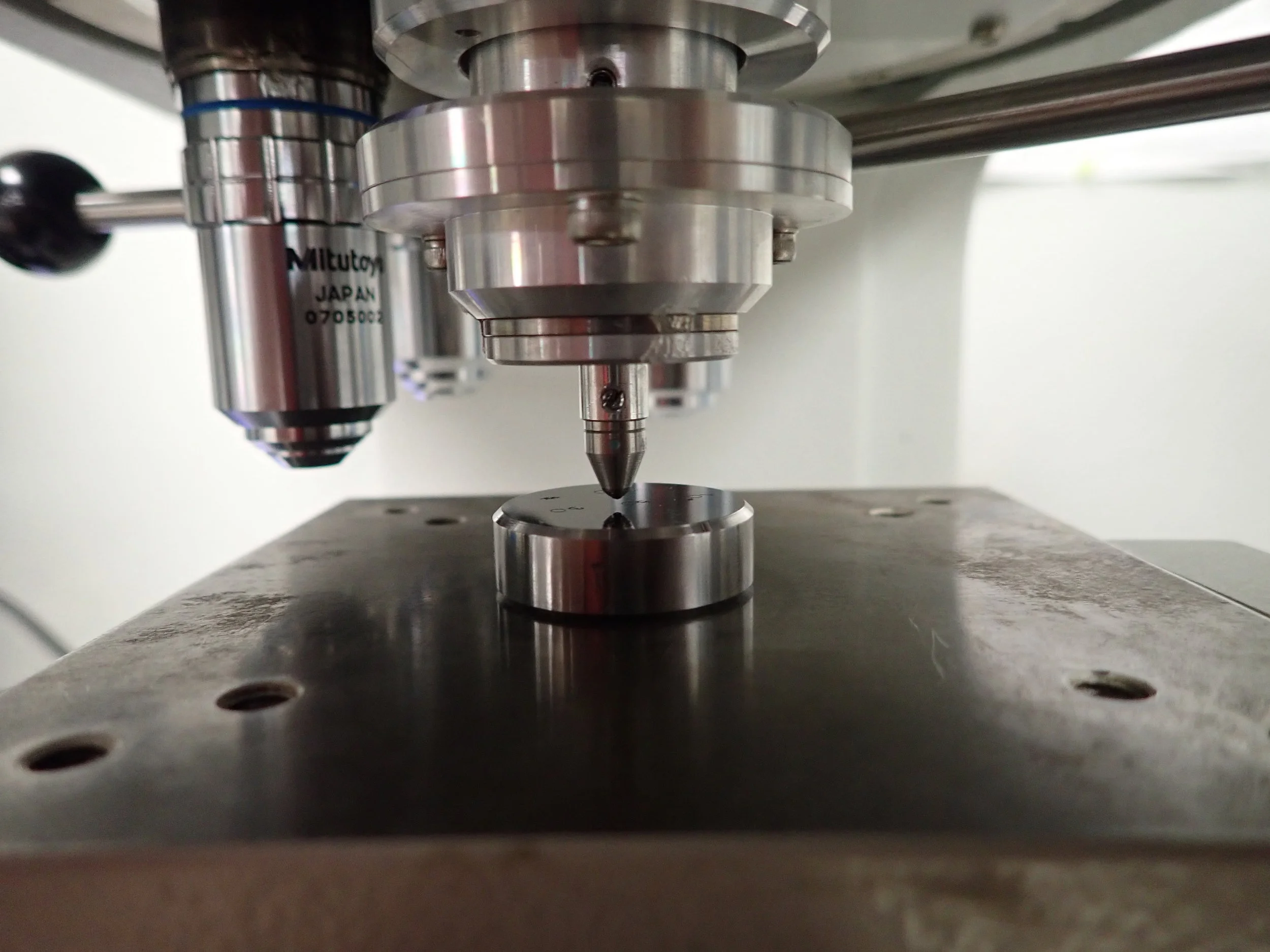

MES utilizes test loads from 10 to 1000 grams using the Knoop or Vickers scales. the Vickers Hardness Test employs a diamond with an apical angle of 136°, and the Knoop Hardness Test uses a narrow rhombus shaped diamond indenter. The test surface usually must be highly polished. The smaller the force applied the higher the metallographic finish required. Microscopes with a magnification of around 500x are required to accurately measure the indentations produced.

CAPABILITIES

Non destructive minus a small indentation

Simple and rapid procedure for fast results

Converts to all common hardness scales

On-site testing of large and/or heavy component or items already installed as parts of a machine

Standardized test methods

SPECIFICATIONS

ASTM A956 - Leeb Hardness

ASTM E18 - Rockwell Hardness

ASTM A833 - Indentation Hardness

SAMPLE REQUIREMENTS

Accessibility to test area

Smooth surface finish free of coatings

Minimum thickness of 1” for Leeb